Wooden Floors

We produce wooden floors in solid and engineered versions. Below we present our collections of wooden floors. We also invite you to explore photos of our floors in interiors in the PROJECTS section.

What Makes Our Wooden Floors Unique?

Our engineered floors feature 4 mm or 6 mm of solid wood top layer and are made on durable, stable first‑grade birch plywood.

You can choose boards, parquet, herringbone and palace panels made from domestic wood (oak, ash, hornbeam) or exotic species (rosewood, merbau, American walnut, doussie, teak, afromosia and many others).

Excellent quality standards resulting from the use of top‑grade materials: European oak and ash, hornbeam, and carefully selected exotic species (in engineered floors – first‑grade birch plywood).

Custom‑made floors – available in non‑standard dimensions and any colour.

Original, exclusive wooden floors: boards up to 9 m long and up to 350 mm wide, as well as unique finishing effects – charred, bleached, hand‑bevelled and aged boards.

Comprehensive installation, including additional work such as screed levelling.

Many years of experience of our specialists and installers, supported by precise production technology.

Installation systems for boards and parquet adapted to underfloor heating.

30‑year warranty on every product – a confirmation of the quality and durability of our floors.

How We Work

Analysis & Offer

Based on the client’s documentation (drawings, plans, inspirations, photos) or after precise measurements performed on site by our team (this service is free), we prepare a detailed offer.

Showroom & Samples

To choose the right floor, clients can view our standard products in the showroom in Kraków. Upon request, we can also prepare several samples and send them to the indicated address or deliver them during measurements.

Production

After consultation and acceptance of the offer and project (regarding placement and direction of boards), we prepare the contract and begin production of the wooden floors.

Installation

Before installation, we check the moisture level of the screed on site using the CM method.

Once all standards are met, we begin the work, which includes priming the screed and gluing oiled or lacquered boards to the floor (this installation usually covers around 40 m² per day). Installing parquet/herringbone or raw boards requires additional steps: after laying the floor, it must rest for approx. 2 weeks, then it is sanded and protected with oil or lacquer. Depending on the floor area, this process may take 2–3 weeks.

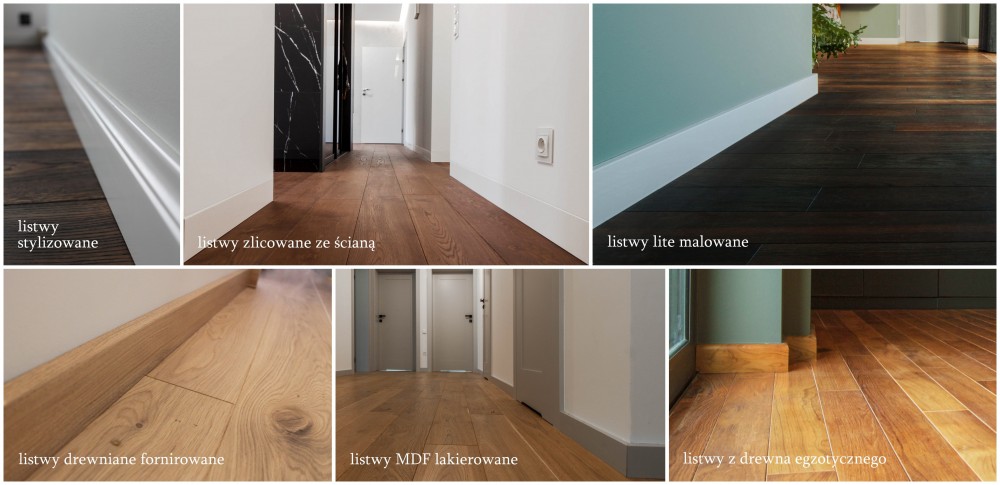

Skirting Boards

We offer all types of skirting boards that perfectly complement wooden floors. Our skirting boards are stylistically and colour‑matched to engineered boards, solid boards, parquet and herringbone floors.

More detailed information can be found in the skirting boards section.

Wooden Grilles for Trench Heaters

Finishing trench heaters is an important element that affects the aesthetics of the interior. We offer wooden grilles placed over underfloor heating channels in two variants:

- grilles that are a continuation of the wooden floor – openings are CNC‑cut in appropriately selected board fragments;

- grilles made of glued wooden elements, in the same species and colour as the floor.

By using grilles made from the same wood species and colour as the floor, we achieve a harmonious and elegant interior finish. The variant made from floorboards creates a unique, exclusive architectural detail.